Address:

Plot No 37/1, 1st Floor, 6th Main, Hosur Rd, Singasandra, Bengaluru, Karnataka 560068

Address:

291 C Narasapura Industrial Area, Sy. No. 15, Karadubande Hosahalli Village, Narasapura Hobli, Kolar Taluk, Karnataka - 563133

In the world of manufacturing and industry, efficiency and precision are paramount. One technological marvel that has played a pivotal role in achieving these goals is the gantry robot. Gantry robots, also known as Cartesian robots, are mechanical systems designed to perform tasks with a high level of precision and repeatability. This article delves into the intricacies of gantry robots, their applications, benefits, and the impact they have had on modern manufacturing processes.

Gantry robots are a type of robotic system characterized by a Cartesian coordinate system. Unlike articulated robots, which have a series of interconnected joints, gantry robots move along linear axes. The primary components of a gantry robot include a rigid frame, linear guides, and a tool or end effector for performing tasks. These robots can be large-scale systems found in manufacturing plants or smaller units used in laboratory settings.

The concept of gantry robots dates back to the mid-20th century, initially used in the aerospace industry for tasks like handling heavy aircraft components. Over the years, their capabilities expanded, and today, they’re found in various sectors.

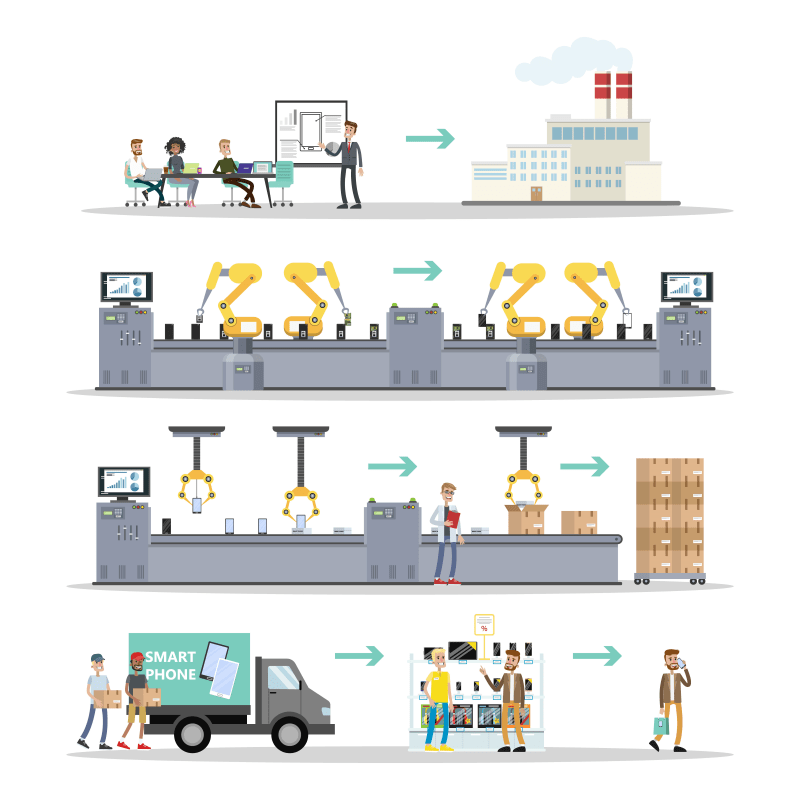

Gantry robots play a pivotal role in modern manufacturing, contributing to increased productivity, reduced human error, and enhanced product quality. They are the driving force behind automated production lines in industries such as automotive, electronics, and pharmaceuticals.

Gantry robots typically consist of a rigid frame (gantry), which moves along tracks or linear guides. Attached to the gantry are motors, actuators, and a tooling system. The linear motion allows precise control in the X, Y, and Z axes.

These robots rely on sophisticated motion control systems, ensuring accurate positioning and movement. Advanced algorithms and feedback mechanisms enable precise control, even in high-speed applications.

Gantry robots are equipped with sensors like encoders and cameras to provide real-time feedback. This feedback loop ensures that the robot adjusts its movements, maintaining accuracy and preventing errors.

Gantry robots are programmed using software that specifies their movements and tasks. They can be programmed for various applications, from simple pick-and-place tasks to intricate tasks in medical device manufacturing.

The frame provides the structure and stability to the robot. It is typically made from aluminum or steel to ensure durability and precision.

Gantry robots rely on linear motion for movement. Linear guides, often equipped with bearings, facilitate smooth and precise motion along the X, Y, and Z axes.

This is the business end of the robot, where the actual work is performed. The end effector can take various forms depending on the specific task, ranging from grippers for material handling to specialized tools for tasks like welding or painting.

Gantry robots employ various drive systems, including ball screws, belts, or rack and pinion mechanisms, to convert rotary motion into linear motion.

The versatility of gantry robots has made them indispensable in a wide range of industries. Some notable applications include:

In manufacturing, gantry robots are commonly used for tasks such as pick-and-place operations, welding, painting, and quality control. Their precision and repeatability make them ideal for ensuring consistent output in high-volume production lines.

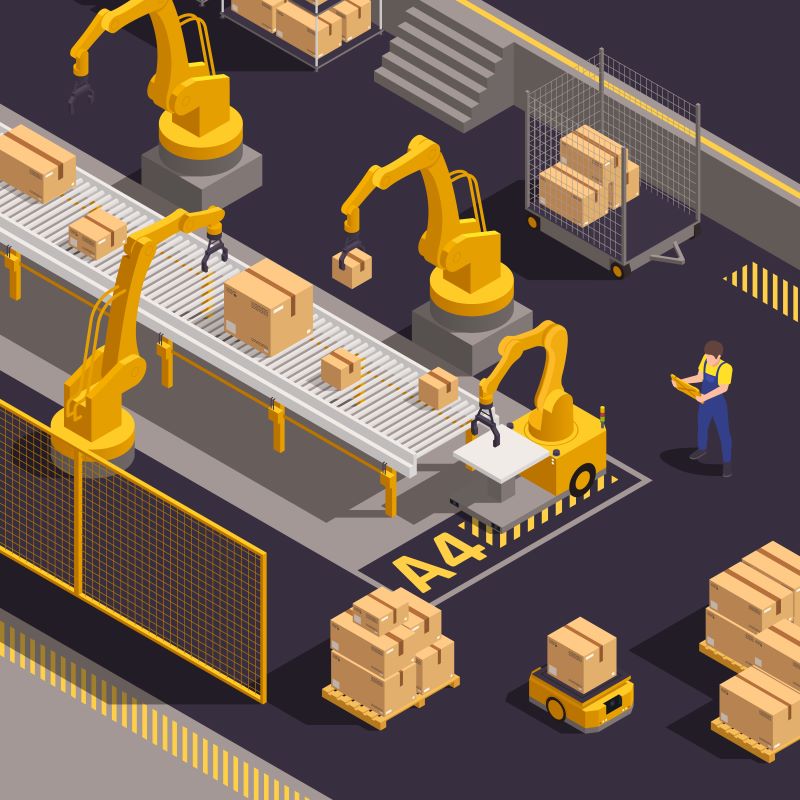

Gantry robots excel in material handling tasks, such as loading and unloading heavy objects, sorting, and packaging. Their ability to lift and move substantial loads with precision reduces the risk of damage and injury.

In modern warehousing systems, gantry robots play a pivotal role in automating the storage and retrieval of goods. They efficiently navigate through aisles, retrieving items with speed and accuracy, thereby optimizing warehouse operations.

In laboratories and medical facilities, gantry robots are used for tasks like sample handling, dispensing, and precision testing. They ensure accurate and reliable results, particularly in high-throughput environments.

Gantry robots are extensively utilized in industries where precision is non-negotiable. In aerospace, they assist in tasks like drilling, riveting, and inspection of aircraft components. Similarly, in the automotive sector, they are integral to processes such as painting, welding, and assembling intricate parts.

The adoption of gantry robots brings forth a multitude of benefits for industries seeking to enhance their manufacturing processes:

Gantry robots are engineered for precision. Their ability to perform tasks with micrometer-level accuracy ensures consistent, high-quality output, which is crucial in industries where even the slightest deviation can lead to defects or failures.

These robots are designed for speed, enabling them to complete tasks in a fraction of the time it would take a human worker. This acceleration translates to increased production rates and higher throughput.

By taking on tasks that are physically demanding or potentially hazardous to humans, gantry robots improve workplace safety. They also eliminate the risk of repetitive strain injuries associated with manual labor.

Gantry robots can be reprogrammed and reconfigured to perform a variety of tasks, making them a versatile solution for evolving production needs. This adaptability future-proofs manufacturing operations against changing demands.

Gantry robots do not require breaks, and they can operate continuously, leading to round-the-clock production capabilities. This is especially advantageous in industries with stringent deadlines.

There are several types of gantry robots based on their configuration and application. Here are some common types:

This type of gantry robot operates along a single linear axis (usually the X-axis or Y-axis). It is suitable for tasks that require movement in only one direction.

This type can move along two linear axes (usually X and Y), allowing for movement in a plane. Two axis gantry robots are commonly used for tasks such as pick-and-place operations.

This type of gantry robot is capable of movement along all three linear axes (X, Y, and Z). It can perform tasks in a three-dimensional space and is widely used in applications like CNC machining and 3D printing.

In addition to the three linear axes, four axis gantry robots often incorporate an additional rotational axis (typically a rotary table). This enables tasks that require rotation or orientation changes.

These gantry robots have all the features of a four axis gantry robot with an added capability for tilting or rotating the tool or end-effector. This is particularly useful for tasks like machining complex surfaces.

This type of gantry robot adds an additional rotational axis to the five axis system. Six axis robots are highly versatile and are commonly used in tasks that require a high degree of dexterity, such as welding or painting.

While not a traditional gantry robot, the delta robot is a type of parallel robot used in pick-and-place applications. It consists of three or more arms connected to a common base, and it is known for its high speed and precision.

This is a large-scale gantry system used in applications such as cargo handling, large-scale machining, and assembly of large components. It typically operates on a rail system.

These are compact gantry robots designed for applications that require precise and compact automation, such as in semiconductor manufacturing or medical device assembly.

This type combines features of different types of gantry robots. For example, it might combine the precision of a three axis gantry with the flexibility of a six axis robot.

Remember, the specific type of gantry robot chosen for a particular application depends on factors such as required degrees of freedom, precision, payload capacity, and the nature of the tasks it will perform.

Continued advancements in materials science and engineering will likely lead to the development of lighter, stronger, and more durable materials for constructing gantry robots. This could improve performance, reduce energy consumption, and enhance the overall lifespan of these machines.

Gantry robots are expected to incorporate AI and machine learning algorithms to enhance their ability to adapt and learn from their environment. This could lead to improved decision-making, better adaptability to changing conditions, and increased efficiency in completing tasks.

Future gantry robots are likely to have enhanced safety features and collaborative capabilities, allowing them to work alongside humans in shared workspaces. This would open up new possibilities for applications in industries like manufacturing, logistics, and healthcare.

Advances in sensor technologies, including vision systems, LiDAR, and other sensing modalities, will enable gantry robots to have a more accurate perception of their surroundings. This can lead to improved object recognition, tracking, and manipulation.

Gantry robots are expected to become more interconnected through the Internet of Things (IoT). This would enable them to communicate with other machines, systems, and even cloud-based platforms for data sharing, remote monitoring, and centralized control.

Future gantry robots will likely focus on energy-efficient designs and sustainable manufacturing processes. This may include the use of energy recovery systems, regenerative braking, and the adoption of eco-friendly materials.

Advances in manufacturing technologies, such as additive manufacturing (3D printing), may enable the rapid prototyping and customization of gantry robot components. This would allow for more tailored solutions to specific applications.

Gantry robots are expected to become more autonomous, capable of making decisions and navigating complex environments with minimal human intervention. This could be especially relevant in logistics and warehousing applications.

Gantry robots may be integrated with wearable exoskeletons or robotic augmentation devices to enhance human capabilities in tasks that require strength, precision, or endurance. This could revolutionize industries like construction and healthcare.

As gantry robots become more versatile and adaptable, they are likely to find applications in a wider range of industries beyond their current domains. This could include fields like agriculture, healthcare, entertainment, and more.

Gantry robots have emerged as a cornerstone of modern manufacturing and industrial automation. Their precision, speed, and versatility make them invaluable assets in a wide range of industries. As technology continues to advance, we can expect gantry robots to evolve further, revolutionizing how we approach production and automation in the years to come. With their potential for increased efficiency and higher quality output, gantry robots are poised to play an even more prominent role in shaping the future of industry.

Inlogsys, a pioneering force in automation solutions, stands at the forefront of delivering cutting-edge gantry robots designed to revolutionize industries worldwide. These state-of-the-art gantry robots represent a culmination of precision engineering, advanced technology, and meticulous attention to detail. Engineered to meet the diverse demands of modern manufacturing environments, Inlogsys‘ gantry robots excel in tasks requiring high levels of accuracy, speed, and repeatability. Looking for one such solution? Contact Inlogsys.

Plot No 37/1, 1st Floor, 6th Main, Hosur Rd, Singasandra, Bengaluru, Karnataka 560068

291 C Narasapura Industrial Area, Sy. No. 15, Karadubande Hosahalli Village, Narasapura Hobli, Kolar Taluk, Karnataka - 563133

88842 22240